Simplified diagram

Background

Pneumatic rubber artificial muscles are one of the actuators that can obtain power by injecting fluid such as air into elastic material like rubber. They are lightweight with high output density, and are free of maintenance and flexible. At present, Mckibben type artificial muscles are a widely-used pneumatic rubber artificial muscle in academia and industry. However, the contraction rate of this artificial muscle is about 20%, which is slightly smaller than that of human muscles, and the rubber tube has a short life span because it wears out due to the slipping of the rubber tube and the sleeve.

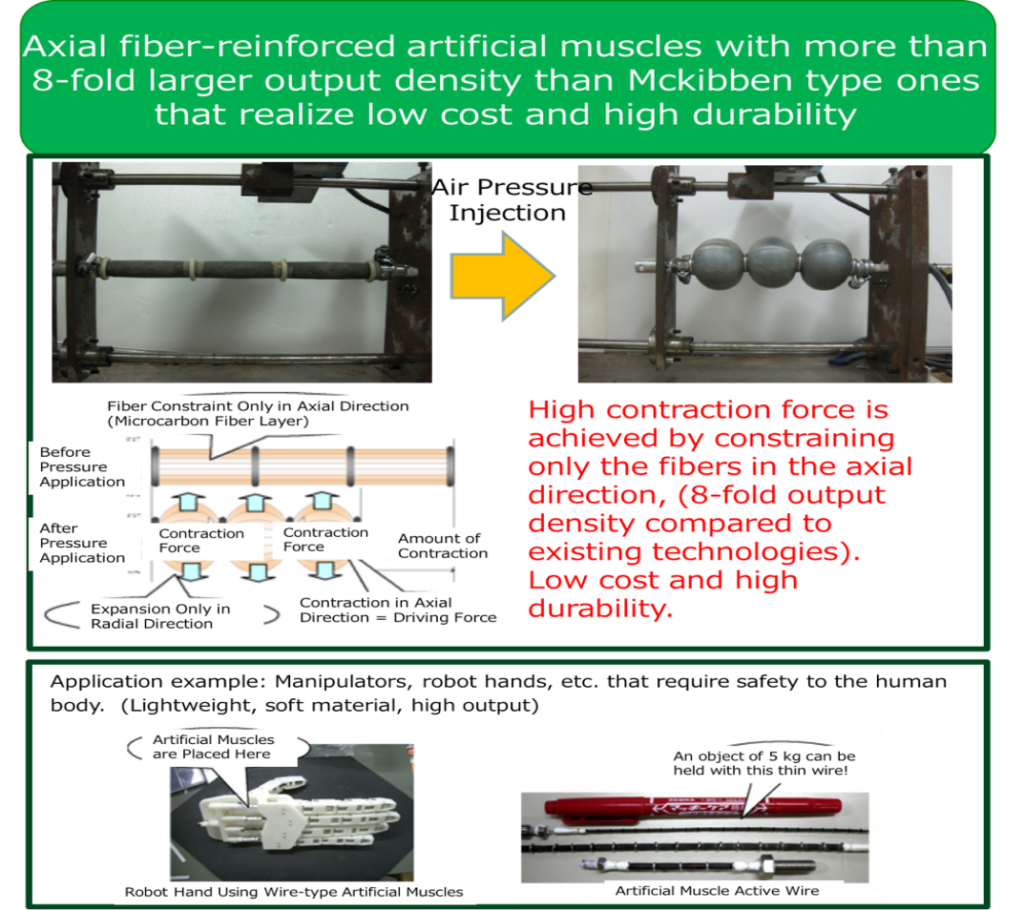

In Nakamura group, we have developed an artificial muscle with an out density eight-fold higher than that of the Mckibben type ones, which is low cost and has high durability. It can be a suitable actuator for mechanical systems that have many opportunities to come into direct contact with humans, such as rehabilitation robots and human body-mounted power assist devices. Since it can be driven in water and powder, it can also be used as an alternative for pneumatic cylinders in factories.We welcome companies that are motivated to commercialize and utilize this technology.

Technical Content

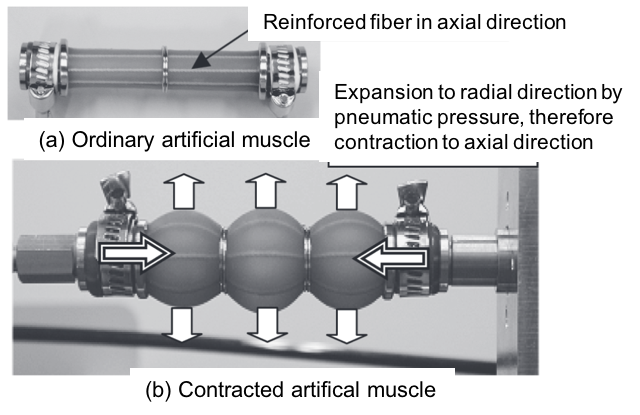

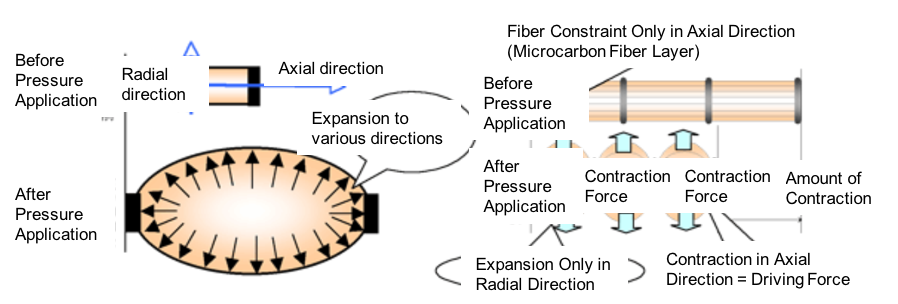

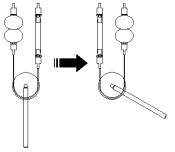

The contraction mechanism of this artificial muscle is that, by constraining the axial direction of the rubber tube with reinforcing fibers, the pressure of the fluid can be directly transmitted as the contraction force of the actuator. The pneumatic supply allows the tube pressure to be transmitted only in the radial direction and not in the axial direction. The rubber tube greatly expands in the radial direction and contracts in the axial direction. Expansion during contraction can be suppressed by the number of rings that are extrapolated into the tube. The following figure shows the artificial muscle before (a) and after (b) applying pneumatic pressure.

The principle of the Mckibben type pneumatic artificial muscles is shown in the following left figure, and the principle of this artificial muscle is shown in the right figure.

In the case of Mckibben type pneumatic artificial muscles, the air pressure is dispersed in all four directions; in the case of this artificial muscle, the contraction force is condensed in only one direction.

The main material is rubber and carbon fiber, so it is inexpensive.

Strengths of the Technology and Know-How (Novelty, Superiority, Utility)

The advantages of pneumatic rubber artificial muscles are as follows:

・High output density can be achieved even with lightweight.

・Can be used in water and has excellent environmental resistance.

・Easy to maintain as there are no sliding parts.

・Flexible and has characteristics similar to muscle properties.

・Low cost of material.

The advantages of this artificial muscle compared to the Mckibben type artificial muscles are as follows:

・Has more than 8-fold larger contraction force (0.5 MPa or more) under the same pressure.

・Possible to reduce the diameter to about 1 mm.

・High durability because the rubber does not wear.

Image of Collaborative Companies

For example, we can work with the following companies:

1) Companies that develop and sell control equipment for robots, such as actuators, robot hands, manipulators, etc.

2) Companies that develop and sell industrial equipment with an emphasis on safety for humans such as rehabilitation equipment and wearable devices.

3) Companies that develop and sell industrial and medical robots.

4) Other companies that are motivated to commercialize and utilize this technology.

Utilization of Technologies and Know-How (Images)

The light and soft material is capable of generating high power, making it suitable for rehabilitation equipment and power-assist devices for the human body, which require safety. It can also be driven in powder and water, so it is expected to be used as an alternative for pneumatic cylinders in factories.

The applications of this artificial muscle are as follows. It can be applied to various purposes depending on the ingenuity of the design.

[Robot Hands]

Robot hands are classified according to their driving method into two types: the built-in actuator type, in which actuators are installed inside each joint, and the wire-connected type, in which actuators are placed outside of the hand and driven via a wire. The former is heavy because it has a built-in motor, and the stiffness of the joint cannot be changed. The latter has the disadvantage that the structure becomes more complicated, for it is affected by the movement of the arm.

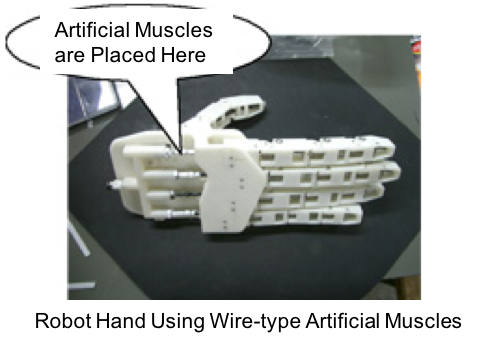

Thus, we developed a robot hand with a wire-type pneumatic rubber artificial muscle with axial fiber-reinforced rubber artificial muscles built into the hand as an actuator. This robot hand has the advantages of lighter weight, flexible joints, simple mechanism and no large space requirement for the drive system compared to other robot hands.

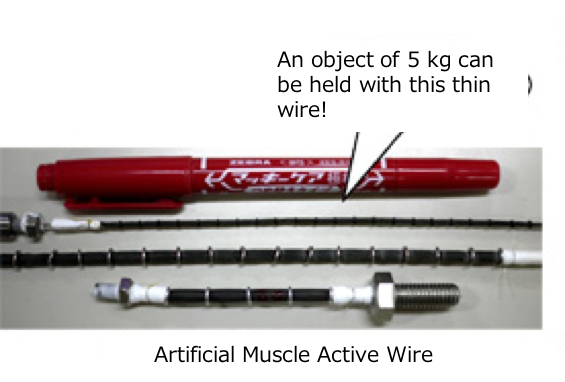

An active wire using artificial muscles is incorporated in this robot hand.

Even though it is thin as 0.9-3 mm in diameter, it can lift up about 50 N because of its large contraction force as an artificial muscle.

(Photo of Robot Hand)

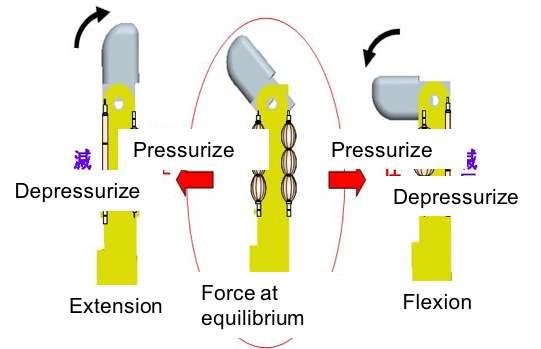

The robot hand uses the wire-type artificial muscles for flexion (bending of the fingers) and extension (stretching of the fingers). Two artificial muscles are placed at each joint for flexion and extension. By placing two artificial muscles, you can also increase the stiffness of the joints.

(Principle of the Robot Hand Movement)

[Multi-Freedom Manipulator]

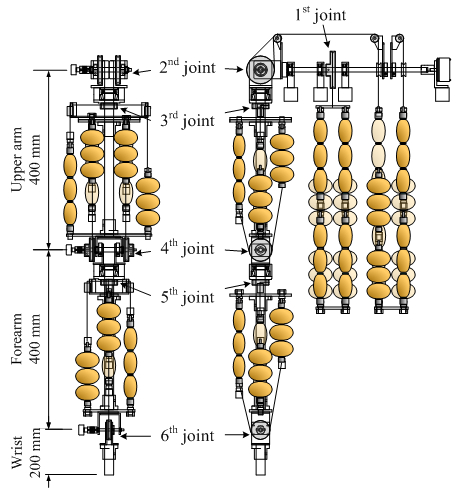

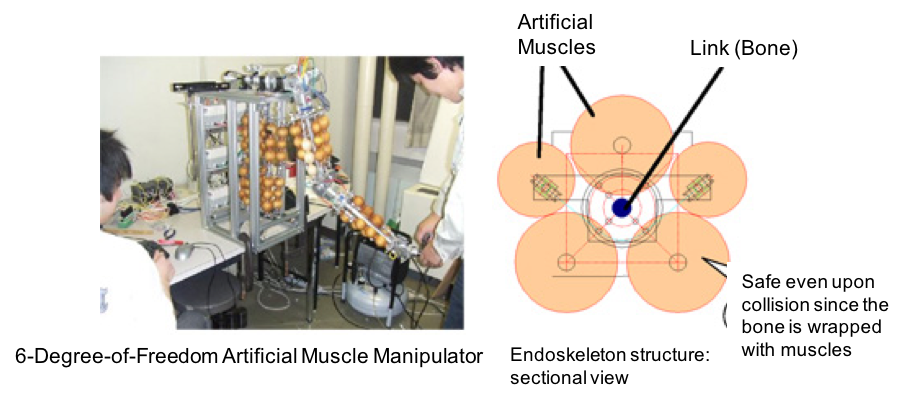

We realized joint arrangement and working range similar to that of a human arm as a 6-degree-of-freedom (DOF) manipulator with 3-DOF for the shoulder, 1-DOF for the elbow and 2-DOF for the wrist. By using lightweight artificial muscles as actuators, the increase in weight associated with the multiple degrees of freedom of the manipulator is reduced. If the output of the driving torque is insufficient in a single row, it is compensated by placing artificial muscles in parallel.

Because the artificial muscles contract in the axial direction, the manipulator is designed to move the joint by antagonism through the wires to the pulley. Pressurizing one of the antagonist muscles and decompressing another result in a pressure difference in the antagonist muscles. This pressure difference causes a difference in the amount of contraction. This difference is converted into a rotational motion by the pulley, which drives the joint.

The actual photo and the internal skeleton structure are as follows. Since the bones are wrapped in the artificial muscles, it is safe even if it collides.

Conventionally, robots capable of performing such complex tasks have had the disadvantages of being very heavy with stiff joints and a weight of more than 50 kg. Also, because of its hard structure, there was a risk of injury if a human came into contact with it.

This manipulator has soft joints and is very light in weight of only about 2 kg, making it safe and easy to use, suitable for cooperative activities with humans.

[Artificial Muscle Manipulator Using MR Fluid]

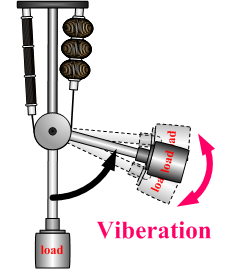

When a heavy object is held by a manipulator, the disadvantage is that the artificial muscles are so flexible that pneumatic pressure causes the holding section to vibrate. Also, if you want to exert a more instantaneous force, there is a limitation in using air pressure.

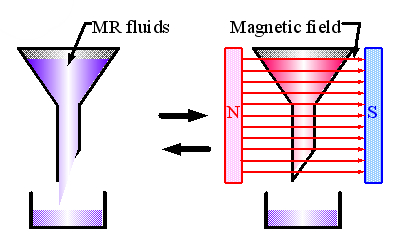

Thus, we tried to apply MR fluid to the joints of an artificial muscle manipulator instead of air pressure. MR fluid is a functional fluid that reversibly alters its apparent viscosity with a high response speed (in milliseconds) by applying magnetic field.

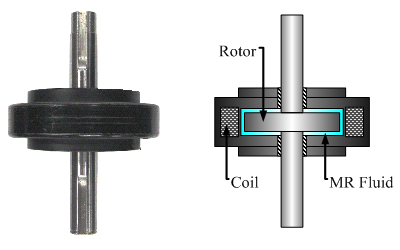

By arranging MR fluid around the inner disc and altering the viscous friction on the disc surface in accordance with the change in magnetic field, the torque can be continuously controlled in response to the rotational movement.

. (Overview of MR Fluid) (MR Brake)

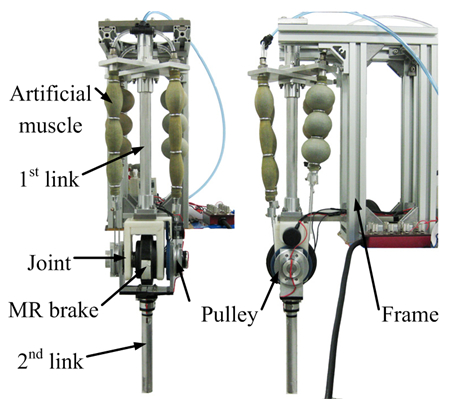

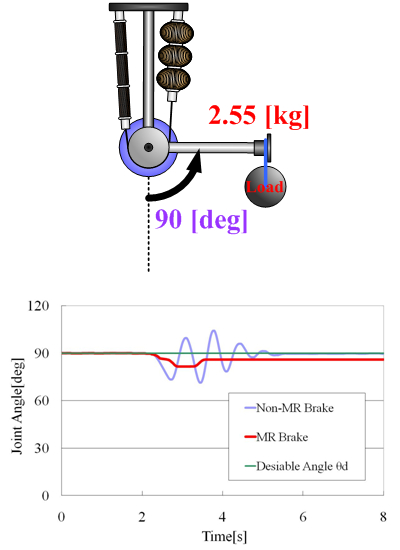

The schematic diagram of the artificial muscle 1-DOF manipulator is shown below. Two rows of artificial muscles are arranged to transmit the contraction force of the artificial muscles to the rotational axis via the pulley.

The MR brake device is fixed to an artificial muscle on one side, which enables the brake to be applied to the axis of rotation. It is equipped with an encoder and a strain gauge to detect the joint angle and the load applied to the link tip, respectively.

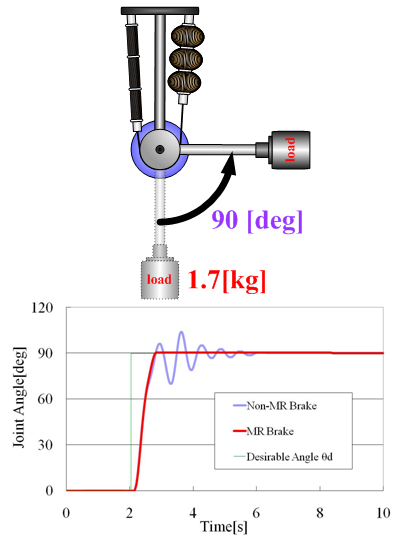

The following is a result of an experiment in which an object is lifted.

In case of pneumatic control, there is vibration (blue line), but there is no vibration when the MR brake is used (red line).

The following are the results of the experiment when an object is held.

When the brake is not applied, the arm drops and vibrates due to the load of the weight (blue line), but when the MR brake is applied (red line), both the drop of the arm and the vibration is suppressed.

It can also be used in various applications.

Flow of Technology and Know-How Application

If you are interested in using this technology or developing products, please feel free to contact us.

We would like to introduce this product with a demonstration.

Description of the Technical Terms

[Artificial Muscles]

Artificial muscle is a generic term for materials that is subjected to some external control to deform its shape, which thereby perform a job. This includes piezoelectric elements that shrink and expand by electric field, gels that deform by differences in ion concentration, and polymers that swell and contract by light.

The artificial muscle shown here contracts and expands by sending air pressure inside the rubber. Since it uses rubber which is soft and safe for human, it is also called a soft actuator.