Schematic Image

Background

Platinum has a high function as a catalyst, but since it is a rare metal, it is required to lower the costs by reducing the amount of platinum consumption while maintaining the function.

With this technology, we propose a new platinum catalyst supported method that is excellent in reuse, reduction, and recyclability.

Technical Content

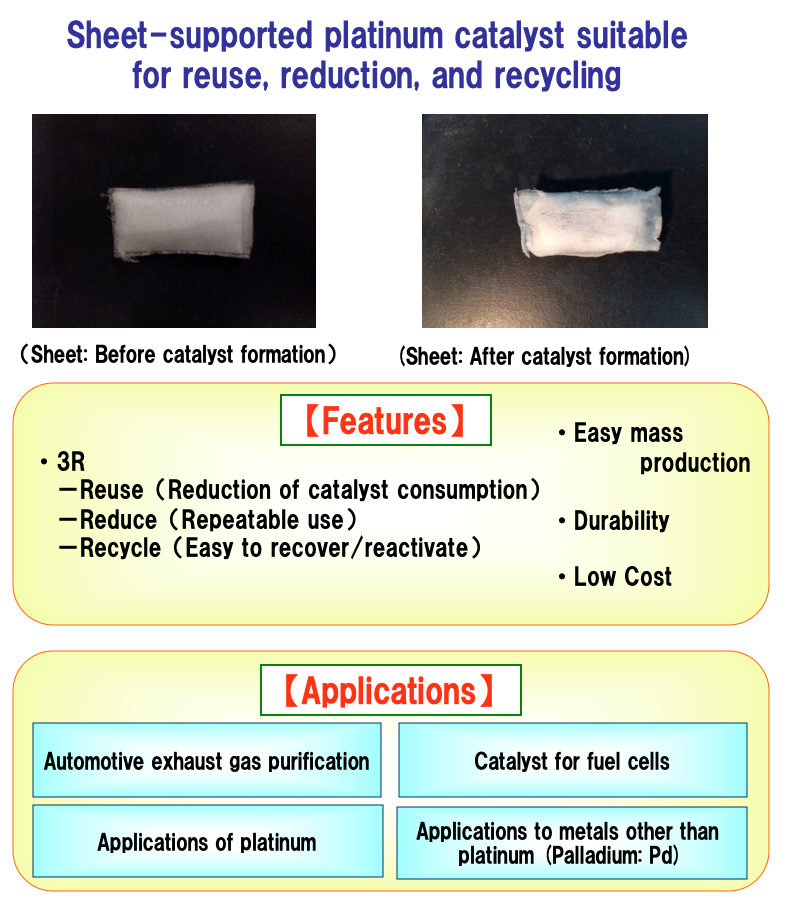

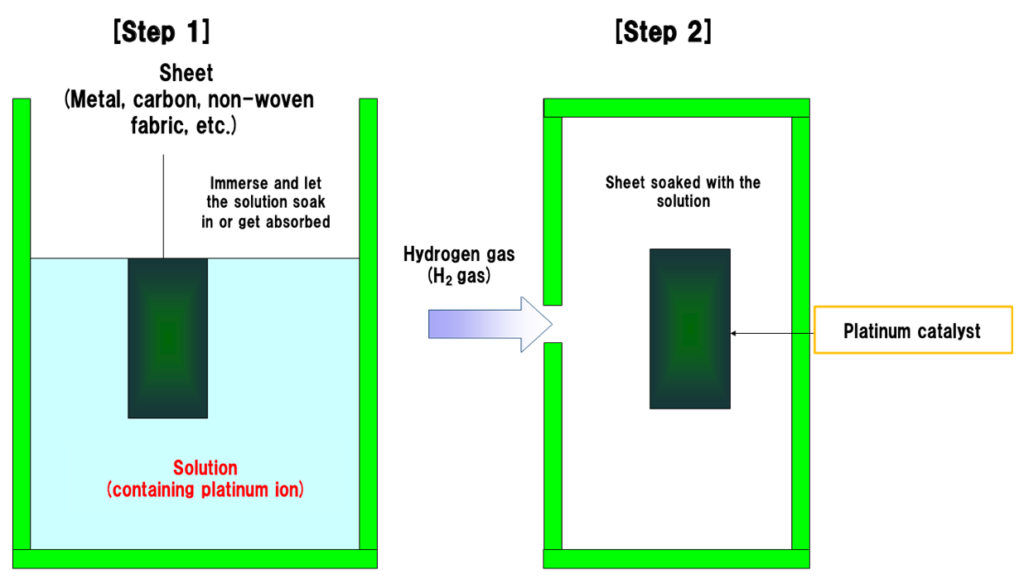

The technology involves sheet supported platinum catalyst. The principles are as follows. The fact that the metal catalyst is loaded on a sheet instead of in powder form is greatly different from the existing technology.

1)Make a solution containing platinum group ions (platinum, rhodium, iridium, ruthenium, or rhenium.)

2)Immerse the sheet into the solution and let the solution soak in or absorb on the surface.

3)Place the sheet soaked with or absorbed the solution under a hydrogen gas atmosphere.

4)Platinum catalyst is formed on the inside and outside surface of the sheet.

The sheet can be made of metal, carbon, non-woven fabric, etc. In the case of metal, absorption to the surface can be performed using a plating technique.

Strengths of technologies and know-how (novelty, superiority, utility)

The advantages of the technology over the existing platinum catalysts are as follows.

1)Repeatable usage (reuse)

-Usually, the platinum catalyst is in the powder form that after the use, is removed with a filter such as a filter paper or Celite that it is used up every time.

In this technology, the catalyst is not a powder type, but rather a sheet type, and that is it not necessary to remove after every use.

For this, it can be used repeatedly until it becomes inactive.

2)Reduction of catalyst consumption (reduce)

-The thickness of the catalyst surface area depends on the thickness of the carrier.

When the thickness of the carrier is reduced, the surface area is increased for the amount of catalyst used that a sufficient catalytic effect can be obtained even with a small amount of catalyst.

3)Easy recovery and reactivation(recycle)

-Since the catalyst is fixed to the sheet, it is easy to recover and reactivate (re-immerse to the platinum-containing solution) after deactivation.

4)Easy mass production

-The process is very simple, only immersing the sheet in a solution and keeping it in hydrogen gas.

-The amount of catalyst carrier can be easily controlled by the concentration and volume of the solution absorbed in the sheet.

-No special equipment is required.

5)Durability

– If the surface does not get poisoned, the durability is sufficient.

Penetration of the solution to the inside of the sheet or absorption at the surface shall be adequate.

6)Low price

-As 3R (reuse, reduce, recycle) is possible and mass production is easy, the cost is low.

Image of partner companies

We welcome companies that wish to commercialize this technology.

For example, we can partner with the following companies.

1)Companies that develop and sell platinum catalysts.

2)Companies that are willing to utilize platinum catalysts.

3)Other companies that develop and sell catalysts of precious metals.

Utilization of technologies and know-how (images)

This technology can be applied to various uses where platinum catalysts are used. For example, the following applications are possible.

1)Exhaust gas purification catalyst for automobile

2)Platinum catalyst for fuel cells

3)Applications of platinum

Also, this technology is applicable to materials other than platinum. Palladium (Pd) has already been experimentally produced.

We welcome companies that wish to apply this technology to other catalysts.

Flow of technology and know-how

The prototype is already available. After your inquiry, we will explain the detailed technical contents at the technical meeting. We can also provide technical consultation on organic synthesis and catalysts not limited to this technology.

Description of technical terminologies

[Platinum Catalyst]

It is mainly used for purifying automobile exhaust gas. Exhaust gases contain various harmful gases, and the concentration and temperature change variously. However, NOx in exhaust gas is oxidized on platinum catalyst in an oxidizing atmosphere, and reduced to nitrogen in a reduced atmosphere by reacting with reducing gases (CO, HC, etc.) on platinum catalyst. By oxidizing and reducing on platinum catalyst, harmful NOx, CO, and HC are converted to harmless substances. In addition, platinum catalyst is also often used as a catalyst for fuel cells.