Simplified

2.45GHz microwave oscillator and atmospheric pressure plasma needle

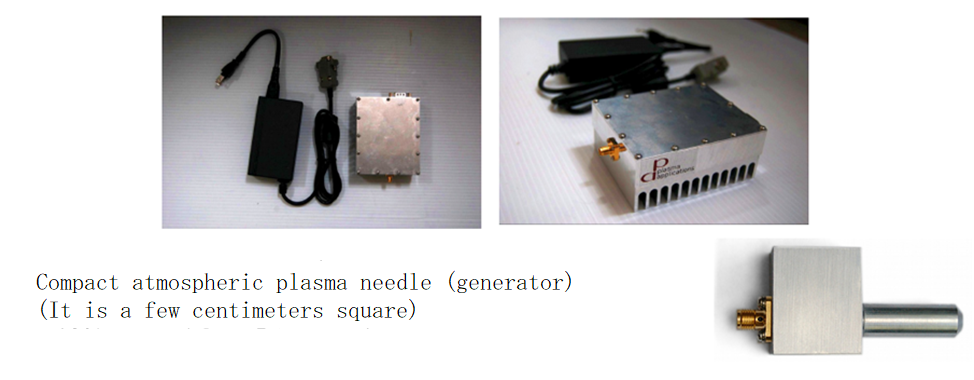

・Compact 2.45 GHz microwave oscillator with square structure shown below (A black color part shows AC/DC power supply to drive the microwave oscillator)

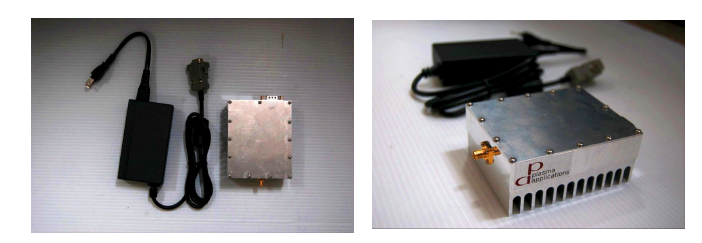

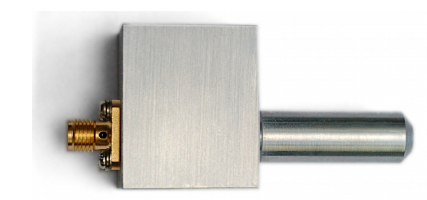

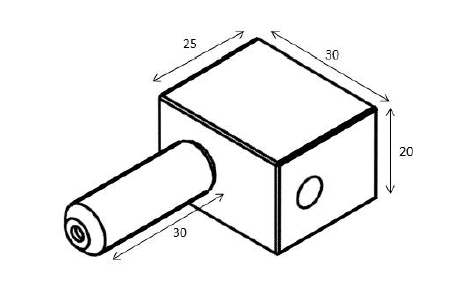

・Compact atmospheric plasma needle generator with W30 mm×D25 mm×H20 mm(except ptruding portion). The picture is shown below.

Fig. Plasma needle generator

| Features of this technology | ||

| Small and inexpensive

hardware |

Wide temperature range

(30℃~1500℃) |

Stable under atmospheric pressure,

easy temperature control |

| Low power consumption (from several watts) | Fine processing (minimum 2 mm in diameter) | Safety for human body, low environment load |

| Application examples of this technology | ||

| Improved adhesion /

paintability |

Sterilization and

disinfect |

Cleaning / organic materials decomposition |

| Hydrophilic property /

Water repellent treatment |

Heat treatment /

micro welding / cutting |

Thin film formation, etc. |

Background

Magnetron oscillators are a well-known diode vacuum tube for 2.45GHz microwave power supply and have been used in 2.45GHz microwave ovens. However, high DC voltage like 4~5 kV is necessary to oscillate it and the life time of most magnetrons is shorter than 5,000 hour. Microwave output power and frequency from magnetron oscillators are not stable so that the plasmas produced by magnetron oscillators are not applied to the fine plasma processing.

Recently, high power transistors (Field emission transistors: FET) have been remarkably developed and their cost decreases year by year. Under such circumstances, high power amplifiers called as solid-state microwave oscillators can get popular replacing magnetron oscillators because of such advantages as compact size, low DC voltage (<50V DC)operation, high stability of microwave output power and frequency and life time longer than 50,000 hours.

There exist many suitable applications that need a precise control of microwave frequency and output power, for instance, plasma generation and fine chemicals. Nowadays, plasma production systems equipped solid-state microwave oscillators have been used in a variety of industrial applications such as surface modification, thin film deposition and thermal processing et al. Mostly, plasmas are generated at the low pressure using the expensive vacuum equipment. Such a problem can be solved by developing the atmospheric pressure plasma production technology.

PAC has developed several type solid-state microwave oscillators and atmospheric plasma needle generator for the small scale fine processing.

We welcome companies that wish to use this technology.

Plasma Applications Co., Ltd. is a university venture established by Professor Masashi Kando of Shizuoka University (formerly) Research Institute of Electronic Science.

Technical Content

The microwave oscillators by PAC use LDMOS FET or GaN FET and are suitable for applications that require precise control of frequency and output power such as plasma generation and fine chemicals by achieving compactness, high efficiency, and long life time.

Plasma needle developed by PAC can produce the plasma under the atmospheric pressure, solving several problems on conventional atmospheric pressure plasma. Especially by combining it with microwave oscillators produced by PAC, the product achieves the excellent performance.

[2.45 GHz Microwave Oscillator]

PAC produces several type microwave oscillators as shown in the Table. These are available for a variety of applications, particularly for the following applications:

・ Low-pressure gas discharge and plasma generation

・ Microwave heating

・ Fine chemicals

- Lamp ignition

- Medical usages

Table List of solid-state microwave oscillators

| Type of microwave oscillator | Catalog Number | Remarks |

| 2.45GHz 10W fixed | SOA-FB245010-01 | PAC products |

| 2.45GHz 50W fixed | SOA-FB245050-01 | |

| 2.45GHz 500mW variable | SOA-VCO24500.5-01 | |

| 2.45GHz 50W variable | SOA-VCO245050-01 | |

| 2.45GHz 100W variable | SOA-VCO2450100-01 | Kowa-Tech*/PAC cooperation products |

| 2.45GHz 250W variable | SOA-VCO2450250-01 | |

| 5.8GHz 50W variable | SOA-VCO5800050-01 | Kowa-Tech products |

| 5.8GHz 100W variable | SOA-VCO58000100-01 | |

| * Kowa tech Co.,Ltd. : Cooperative company of PAC | ||

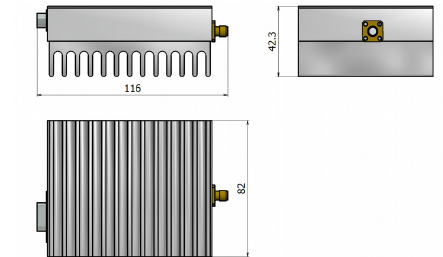

The plasma needle generator uses the low microwave power from the microwave oscillator SOA-FB245010-01, which will be introduced as an example of microwave oscillators produced by PAC. The figures below are the appearance of SOA-FB245010-01.

Features :

・LDMOS FET or GaN FET is used.

・Microwave conversion efficiency against AC power : ~ 50 %

・Small (116x82x42.3 mm) and lightweight

・Long life (> 50,000 hours)

・Incident and reflective power monitors

・Microwave output is fixed at 10 W. Output Variable (0 ~10 W) type can be produced depending on the request.

The size (the unit in the diagram is mm) is shown below (Remark: the half size 10W microwave oscillator is under development).

Fig. Design of SOA-FB245010-01

Table Main specifications of 2.45GHz microwave oscillator

Output power :10 W fixed (SOA2.45G10W)

| Item | Specifications | |

| Power supply | Voltage | +28 VDC±0.2V(MAX) |

| Current | 1 A(MAX) | |

| Microwave frequency | One frequency between 2.45GHz and 2.50GHz can be specified | |

| Microwave output | 10 W fixed | |

| Operating temperature | -10℃~+45℃ | |

| Interface | Microwave output | SMA connector |

| Power supply | D-Sub (9 pin) connector | |

| Size | W82mm×D116mm×H42.5mm (heatsink is included but protruding portions are excluded.) | |

[Plasma Needle Generator]

Fig. Atmospheric plasma needle generator (PLN-1)

The injection of microwaves and argon gas in the 2.45 GHz band allows the plasma to be generated in needle-like form under atmospheric pressure. The antenna is housed inside the metal tube (the tubular projection on the right side of the top view), and the microwave leakage to the outside of the microwave is kept at the low level.

The principles are as follows.

1) The DC voltage (~28 V) from AC/DC converter is applied to the solid-state microwave oscillator. The microwave propagates along the antenna on the central axis in the metallic tube.

2) The argon gas for instance is injected through the metal tube.

3) Plasma is generated at the contact parts such as microwave radiation and argon gas. Temperature of the plasma can be adjusted by the microwave output and gas flow rates and gas species.)

4) The plasma extends along the gas injection with a needle-like shape.

The plasma needle length depends on not only the gas flow rate but microwave input power. The needle-like plasma are ejected from the tapered metal tube opening. The buffer gas (argon) can be supplied from the side or opposite surface.

The dimension of the plasma needle is as follows (Unit is mm) :

Fig. The dimension of the atmospheric plasma needle generator (PNL-1)

Table Main Specifications of atmospheric plasma needle generator

| Item | Specifications |

| Microwave input power | 5-20 W |

| Microwave frequency | 2.45 GHz |

| Argon / air mixed plasma needle tip temperature | Depend on the gas flow rate, gas mixture and microwave power. Typically, it is around 70 ℃ for the microwave power lower than 10 W and increase with microwave power. |

| Argon gas flow rate | 500-2500 SCCM |

| Microwave input connector | SMA(plug or jack) |

Strengths of technologies and know-how (novelty, superiority, utility)

[2.45 GHz Microwave Oscillator MPS – 10A / 10B]

The features of this technology are as follows.

1) Compact size, long life and rather high efficiency.

2) Frequency and output are stable.

It can be applied to small volume plasma generation, local microwave heating, and fine chemicals et al.

[Plasma Needle (Generator)]

There is another atmospheric pressure plasma generated by high frequency (typically 13.56 MHz), well known as the Dielectric Barrier Discharge (DBD). DBD Atmospheric plasmas have many excellent properties such as low temperature and flexible structures et al so that a variety models have developed depending on the applications. In the present technology, the 2.45 GHz microwave is used, and original mechanisms for atmospheric plasma generation are devised to take various advantages. The features of this technology are as follows.

1) The plasma can be generated by low power microwave with compact tuner and all microwave parts can be connected by flexible SMA coaxial cable. Therefore the overall hardware configuration becomes simple, compact and inexpensive.

The feeding gas can be selected to fit the application with cheaper buffered gas (argon). By combining with the compact solid-state microwave oscillator, it is possible to generate stable plasma needle with a small size and low cost.

2) Because of the atmospheric pressure plasma, the large scale and expensive vacuum chamber is not required and user friend and easy handling plasma needle can be realized.

3) By adjusting not only microwave input power but gas species and flow rates, property of plasma needle ejected from the tapered metal opening are remarkably modified, which will allow a variety of applications.

Since argon is mainly used as the buffer gas mixed with small amount of air, the ozone production is negligibly small. On the other hand, when oxygen or air at an appropriate pressure is mixed into argon, oxygen radicals can be produced in the plasma needle and chemical reaction activity will be much enhanced.

4) Stable control of plasma needle temperature.

If the microwave input power is lower than 10 W, the temperature of the plasma needle tip can be kept lower than 70 ℃, though it depends on the microwave input power, the gas flow rate and the gas species. The temperature of the object (e.g., substrate) on which the plasma needle is irradiated can be automatically controlled by using a temperature sensor.

If the microwave input power exceeds 20 W, the plasma temperature rises and the plasma tends to the thermal plasma.

5) Low microwave power consumption (from 1 W to 20 W), which leads to the battery usage and to suppress the running cost. The feature can realize the user friend systems with the built-in or non-contact wire-less power supply (e.g., the magnetic resonance system, etc.), making it possible to develop the AC power-less or wire-less systems. The built-in wireless module can allow the operation from a remote location.

6) Fine processing is possible.

The plasma needle is a localized plasma, whose spot diameter is about 2 to 3 mm. If necessary, it is possible to make it smaller. On the other hand, the spot diameter can be wider than 10 mm by bundling the several plasma needles or by adjusting the gas flow or modifying the tapered metal tube opening structure.

7) Environment friend and safety to the human body.

Because of argon discharge, there is little ozone production. Microwave leakage from the plasma needle generator is suppressed perfectly. Therefore, the plasma needle system is safely against the human body.

[Comparison with vacuum or low pressure plasma generator」

Expensive vacuum systems are used to evacuate the discharge chamber to low pressure. To keep the discharge chamber low pressure and clean, it is necessary to use the automatic pressure control systems or the operators with high skill and knowledge. In general, the plasmas produced in the low-pressure discharge system have lower plasma density which makes the low reactivity.

「Comparison with other atmospheric pressure plasmas」

Most of other atmospheric pressure plasmas use dielectric barrier discharges (DBD) since they can produce non-thermal equilibrium plasmas with various modified structures. In the present, DBD plasmas are widely used as Ozone generators, excimer discharges or low temperature plasma torches. Thus, it is a strong competitor of our plasma needle generation.

Image of a cooperative company

We welcome to companies that wish to introduce this equipment and apply this technology. For example, we can cooperate with the following companies.

1) Companies and research institutes related to microwave plasma devices and applications

2) Companies and research institutes related to microwave circuits and applications, not limited to plasma

3) Companies that have introduced the plasma process into the process, or the companies that are considering the introduction of the plasma process.

4) Companies that wishes AC power-less or wire-less or remote control systems of the plasma processes.

5) Companies which develop and sell medical treatment equipment in the medical or health care field.

6) Companies that are enthusiastic about the business development based on this technology.

Utilization of technologies and know-how (images)

Plasma needles can be developed into many plasma processes.

The followings are several examples:

1) Adhesion / coating properties

* Application Example : Adhesion of solder and adhesion of plastics difficult to adhere

2) Improvement of hydrophilic property / water repellency

* Application example : Improvement of glass surface wettability

3) Other surface modifications and etching et al.

4) Thin film formation

* Application example: Carbon thin film, etc.

5) Cleaning / organic materials decomposition

* Application example : VOC decomposition

In addition, the benefits of low-temperature plasma can be used to develop new therapeutic applications.

6)Treatment

* Application example : Sterilization application, body surface disease treatment (recently drawing attention)

Flow of technology and know-how

The experimental equipment for atmospheric pressure plasma needle is ready. We also explain the details of the technology. Please feel free to contact us regarding usage.

Description of the technical terms

【LDMOS FET (Laterally Diffused MOS FET) and GaN FET】

LDMOSFET: LDMOSFET is a MOS FET with a structure that laterally diffuses impurities in the vicinity of the drain. It has high voltage resistance, and it has been used for power amplifiers of mobile phone base stations.

GaN FET: GaN FET is a field-effect transistor using gallium nitride, which is the latest high-power transistor in terms of heat resistance and conversion efficiency. The price has fallen year by year, and rapid spread has started.

【Plasma generated under atmospheric pressure】

Generally, with decreasing the pressure to generate the plasmas, the electron mean free path becomes a length suitable for starting and maintaining discharge. Thus, applied voltage and electric power become enough low to sustain and control the plasma at the pressure lower than 0.01 Pa. However, the technology of the atmospheric pressure plasma generation is evolving under an appropriate condition of discharge voltage and power. Nowadays, it is widely applied to plasma processing because it is the low temperature plasma produced without vacuum systems.